Description

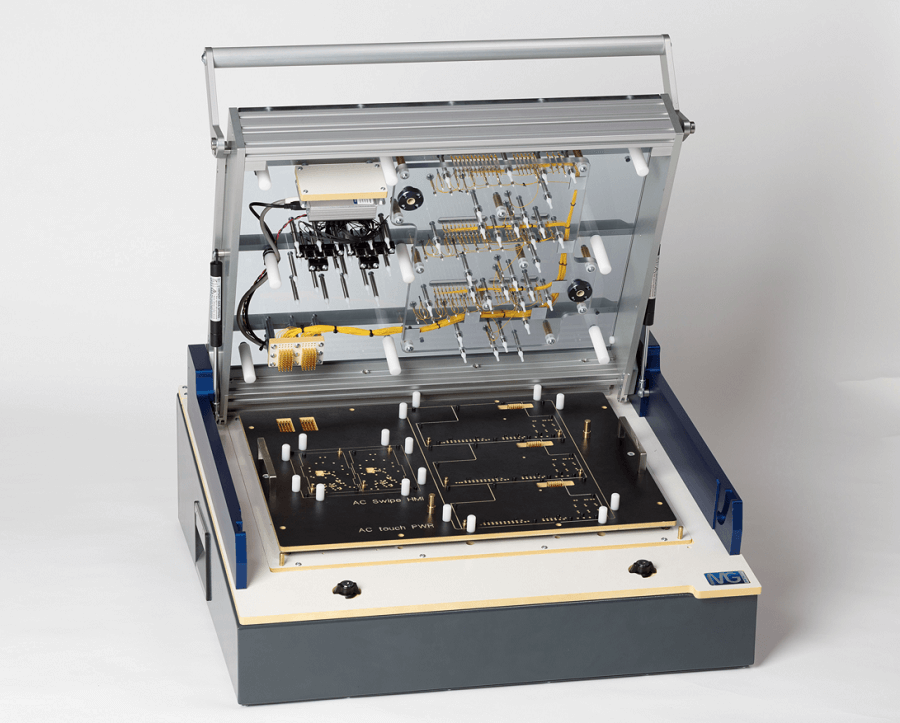

What is an Inspection Jig?

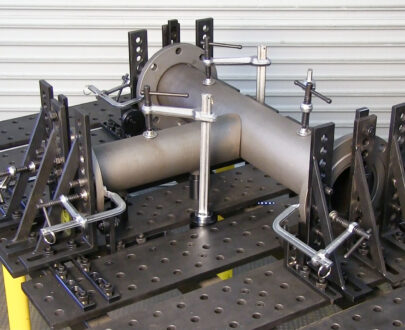

An inspection jig is a specialized fixture used to evaluate the accuracy, dimensions, and quality of a product during manufacturing and assembly processes. It ensures that each component meets quality control standards before final production.

Trusted Inspection Jig Design & Manufacturing

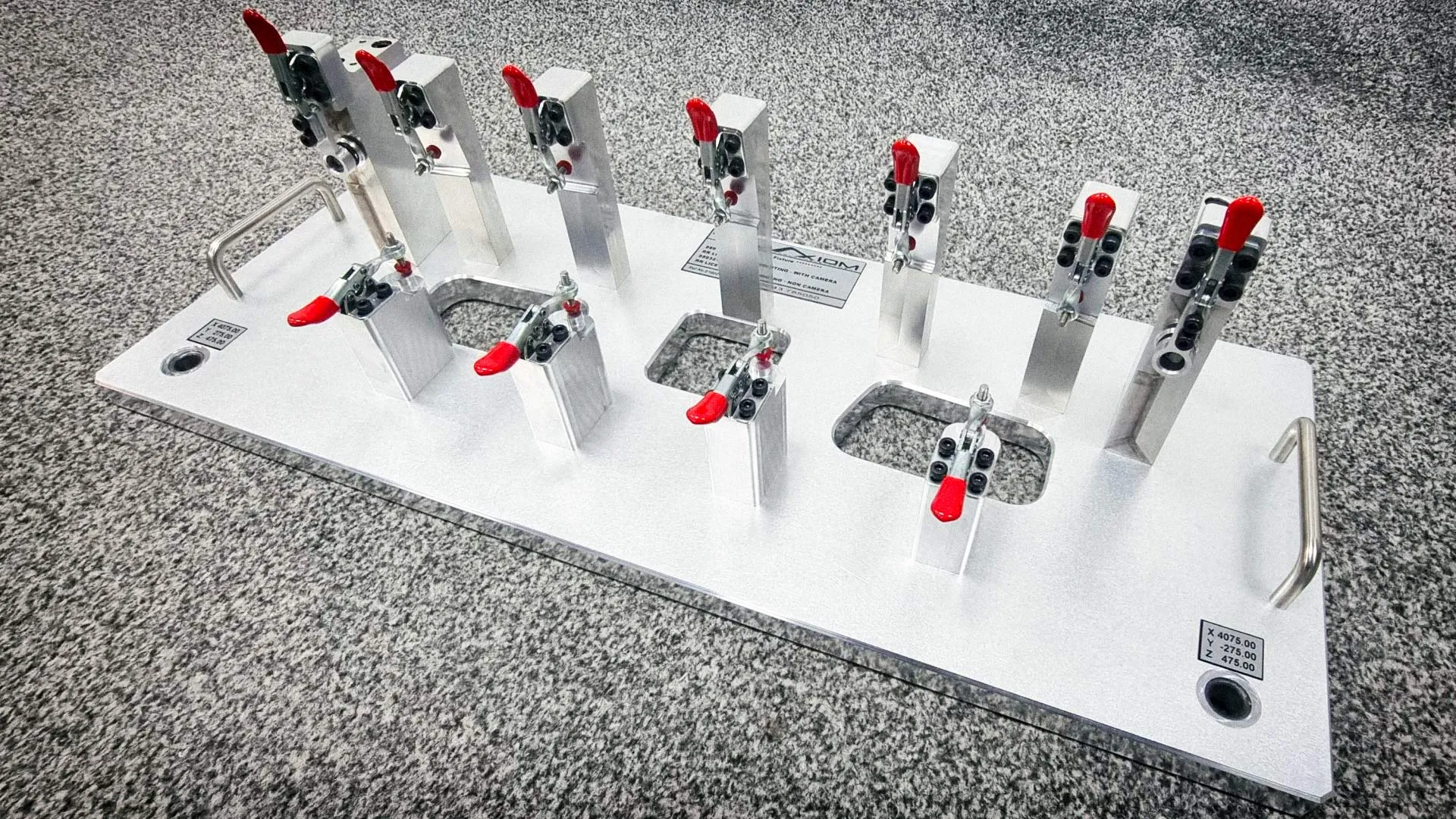

At HM-VH, we specialize in designing and manufacturing high-precision inspection jigs for industries such as automotive, mechanical engineering, and electronics. Our solutions are customized to meet exacting client specifications, ensuring high accuracy and efficient quality control processes.

With years of expertise in automated inspection solutions, we provide multi-functional, high-precision jigs that improve manufacturing efficiency.

Structure of an Inspection Jig

Inspection jigs come in various forms based on specific testing requirements, including dimension measurement jigs, profile inspection jigs, and surface quality control jigs. However, all inspection jigs share these fundamental components:

-

Base Frame – Provides a sturdy structure.

-

Positioning Mechanism – Ensures precise alignment of the test piece.

-

Clamping System – Holds the product securely in place.

-

Measurement & Inspection Mechanism – Includes sensors, gauges, or other testing tools.

-

Additional Components – Depending on specific inspection needs.

The Role of Inspection Jigs

-

Ensures Accurate Quality Control – Measures and evaluates product dimensions against required specifications.

-

Reduces Inspection Time – Automated and semi-automated inspection jigs speed up the QC process.

-

Enhances Manufacturing Efficiency – Identifies defective parts early, minimizing production waste.

-

Optimized for Various Testing Needs – Used for flatness, concentricity, friction testing, fatigue testing, static load testing, and dynamic load testing for automobile and electronic components.

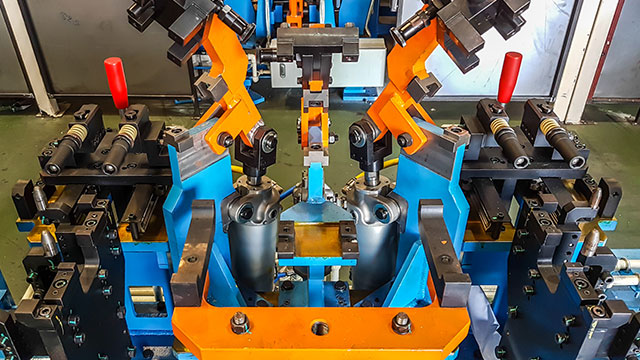

Advantages of HM-VH’s Inspection Jigs

✅ High Precision & Reliable Results – Designed with advanced sensors and measurement tools from Europe and Japan.

✅ Fast & Easy Operation – Allows quick part placement and removal, adaptable to different product models.

✅ Durable & Rigid Structure – Built to withstand forces generated during testing and quality inspection.

✅ Seamless Integration with Automated Systems – Works with robotic arms, feeding systems, and digital measurement displays for real-time QC.

✅ Optimized for Special Environments – Uses wear-resistant, heat-resistant, and moisture-resistant materials for long-lasting durability.

Why Choose HM-VH for Inspection Jig Manufacturing?

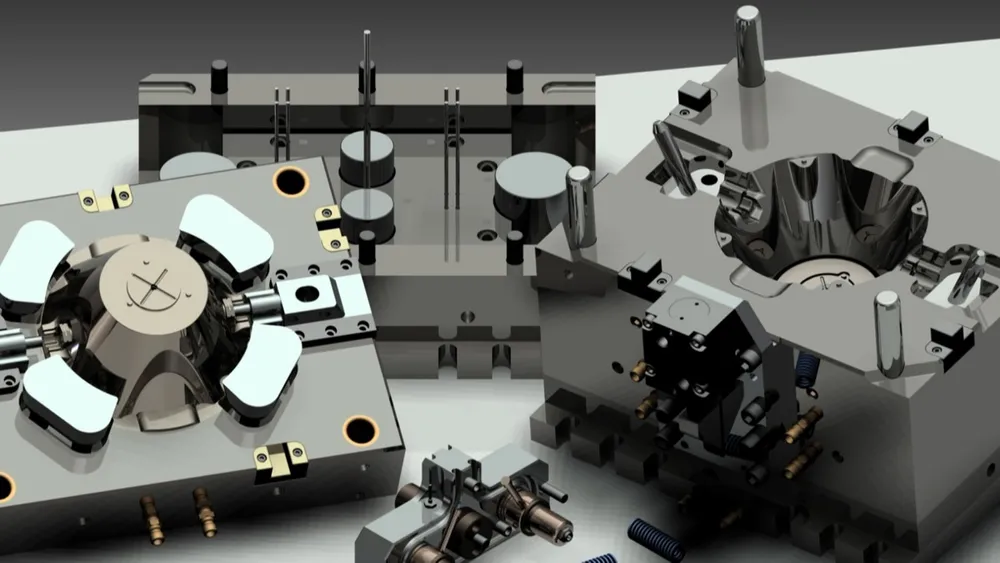

Our inspection jigs are 3D modeled and optimized before production, ensuring ease of use, durability, and extreme accuracy. We offer:

-

Custom inspection jigs for various quality control applications.

-

Advanced automation solutions for efficient QC processes.

-

Reliable delivery & cost-effective solutions tailored to industry needs.

📞 Contact us today for precision inspection jig manufacturing solutions!

Reviews

There are no reviews yet.