Description

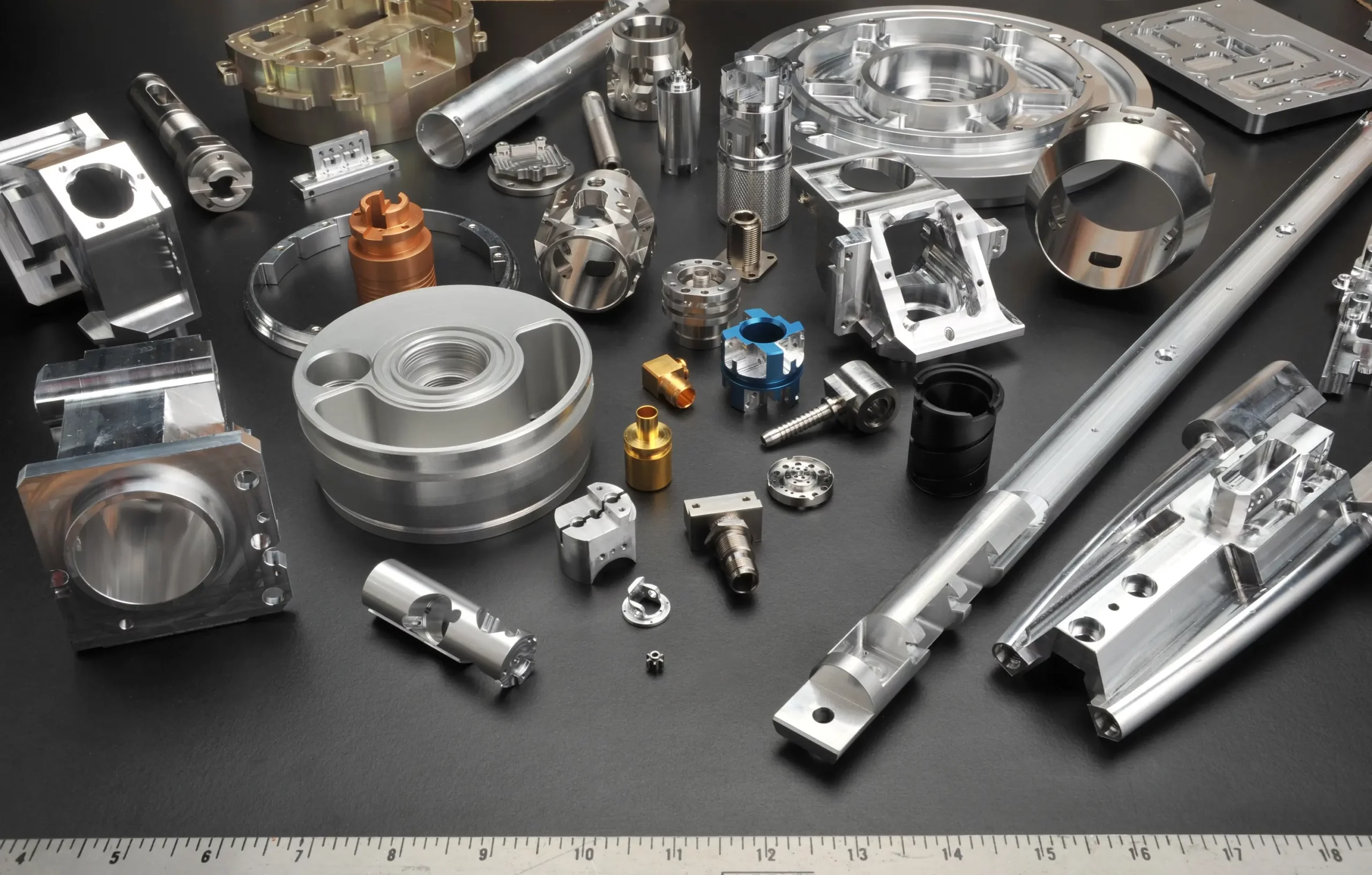

Precision Machining of Motorcycle Spare Parts

Machining motorcycle spare parts or other mechanical components requires exceptional attention to detail. As such, these processes rely heavily on advanced machinery and equipment. This demands significant investment in technology and equipment by companies to meet the high standards of precision required for quality production.

Top-Notch Quality Standards:

-

Customer-Centric Service: We prioritize customer satisfaction with high-quality products, professional services, and competitive pricing. We actively listen to our clients to continually improve our products and services.

-

Skilled Workforce: Our focus on training and developing human resources ensures a highly capable team dedicated to achieving the best outcomes.

-

ISO 9001 Compliance: We adhere to current ISO 9001 standards and continually improve our management system to enhance production and business efficiency.

-

Quality Assurance: Every product undergoes rigorous quality checks at every stage to ensure only the best reaches our clients, helping to build trust in our brand.

-

Long-Term Partnerships: We collaborate sincerely with our suppliers, supporting mutual growth and focusing on customer satisfaction.

Professional and Creative Team

At HM-VH, we pride ourselves on our highly professional team, from management to technicians and customer service staff. With effective leadership, we ensure that our processes run smoothly and efficiently. Our team’s expertise, coupled with years of experience, guarantees that every detail is meticulously crafted, ensuring precise and high-quality motorcycle parts.

Modern Equipment and Technology

Our investment in cutting-edge machinery and equipment is crucial for delivering high-quality motorcycle spare parts. The use of advanced CNC technology allows us to meet the demands of precision, speed, and efficiency. We continuously update and upgrade our equipment to ensure we can meet both domestic and international market standards, especially for export markets.

Motorcycle Spare Parts Machining Process

Using advanced CNC technology, we ensure the highest level of precision and efficiency. Our process for machining motorcycle spare parts includes the following steps:

-

Customer Requirements: Initially, we collect detailed requirements from our customers to ensure we fully understand their needs.

-

Design and 3D Simulation: After gathering all necessary information, we create detailed designs and 3D simulations to provide precise specifications for machine operation.

-

Material Selection: Based on customer requirements, we carefully select the raw materials for the machining process, adjusting machine settings to ensure optimal results.

-

Machining: Each part undergoes precise machining using the appropriate technology, with a strict process flow to ensure accuracy.

-

Inspection and Packaging: After machining, the parts are polished, ground, or sandblasted to enhance precision. We then conduct thorough inspections before packaging and delivering the final products.

Why Choose HM-VH for Motorcycle Parts Machining?

With our meticulous process and top-tier equipment, HM-VH ensures that every motorcycle spare part we produce meets the highest standards of quality and precision. Our commitment to customer satisfaction and excellence makes us a reliable partner for your machining needs.

Reviews

There are no reviews yet.