Description

In today’s industrial landscape, efficiency and precision are crucial. Welding jigs are essential tools that enhance welding accuracy, speed, and consistency. These fixtures are widely used in industrial manufacturing to streamline welding processes, ensuring high-quality results.

What is a Welding Jig?

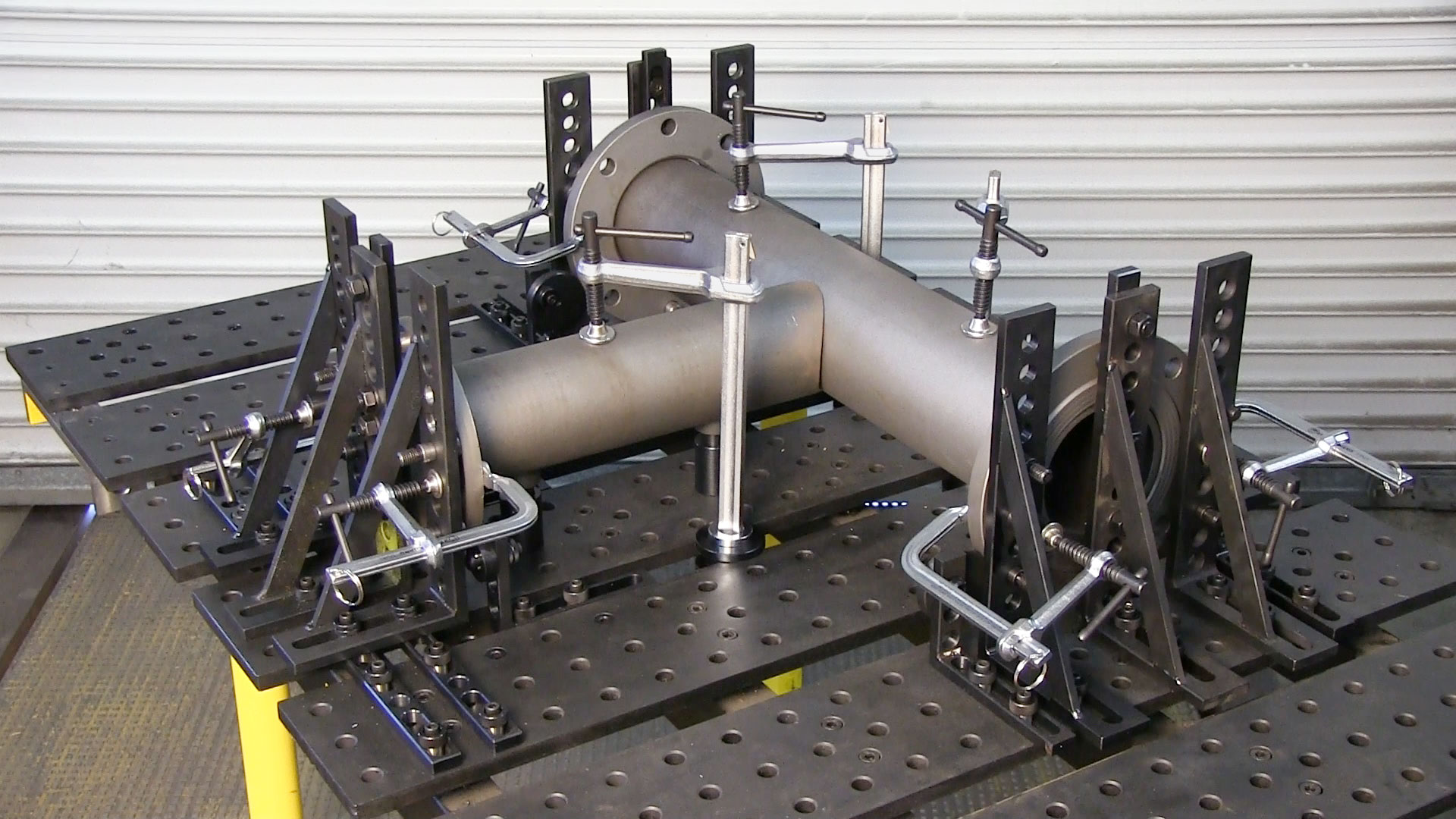

A welding jig is a fixture designed to hold and position workpieces securely during welding. It ensures precise alignment, reducing errors and increasing efficiency in manual and robotic welding applications. Different jigs are available depending on the welding method, such as MIG or arc welding, ensuring optimal fabrication conditions.

Components of a Welding Jig

Regardless of the type, welding jigs share common components:

- Positioning Elements: Ensure accurate placement of workpieces using locating pins, clamps, or stops.

- Clamping Mechanism: Holds the materials firmly during welding to prevent movement.

- Force Transmission System: Distributes clamping force efficiently through screws, gears, or hydraulic systems.

- Guiding Mechanism: Facilitates smooth movement and precise positioning using rails or rollers.

- Base Frame and Stand: Provides structural support, typically made from durable materials like steel or cast iron.

- Machine Mounting System: Secures the jig to the worktable or welding equipment, ensuring stability.

Why Use a Welding Jig?

Welding jigs play a crucial role in metal fabrication, assembly, and quality control. Their benefits include:

- Accurate positioning for consistent, high-quality welds.

- Firm holding to minimize shifting, reducing errors and enhancing safety.

- Increased efficiency by allowing welders to focus on welding rather than positioning materials.

- Higher productivity with faster welding cycles and fewer reworks.

- Cost savings by reducing material waste and labor time.

Types of Welding Jigs

Selecting the right welding jig depends on the application. Here are the most commonly used types:

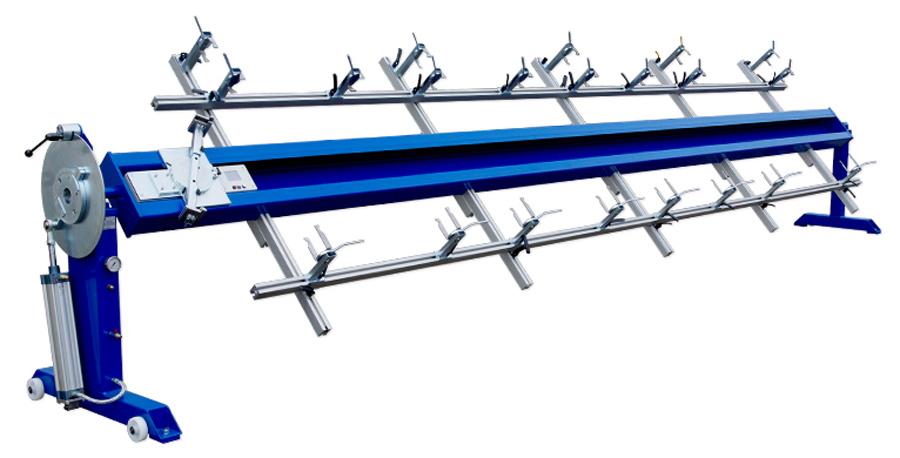

1. Frame Welding Jigs

Used for welding structural frames, ensuring proper alignment and perpendicularity.

- Features: Steel frame, adjustable clamps, and locking mechanisms.

- Benefits: Guarantees precision, reduces distortion, and increases productivity.

- Applications: Machinery frames, industrial equipment, vehicle structures, and prefabricated steel buildings.

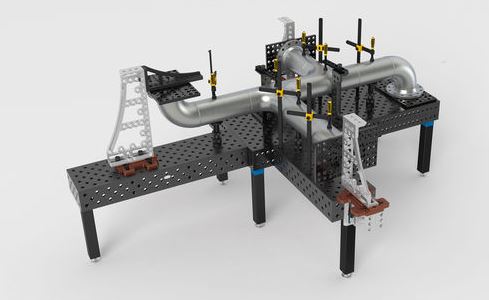

2. Universal Welding Jigs

Designed for versatile use, allowing adjustments for different workpieces.

- Features: Modular design with movable clamps and adjustable arms.

- Benefits: Suitable for various shapes and sizes, reducing the need for multiple jigs.

- Applications: General metal fabrication, railing, doors, gates, and mechanical components.

3. Right-Angle Welding Jigs

Ensures accurate 90-degree welds for strong and clean connections.

- Features: Magnetic or mechanical clamps for stability.

- Benefits: Eliminates errors in angular welding, making it easy to maintain straight edges.

- Applications: Steel beams, construction materials, piping, and machinery parts.

Welding Jig Applications

Welding jigs are indispensable in various industries, ensuring efficiency and consistency:

- Aerospace: Manufacturing aircraft frames, engine components, and landing gear.

- Automotive: Assembling car bodies, chassis, and precision welding parts.

- Shipbuilding: Welding large steel plates and complex ship components.

- Metal Fabrication: Producing machine housings, support structures, and heavy-duty equipment.

- Construction: Aligning and securing steel beams, columns, and reinforcements.

HM-VH: Your Trusted Welding Jig Manufacturer

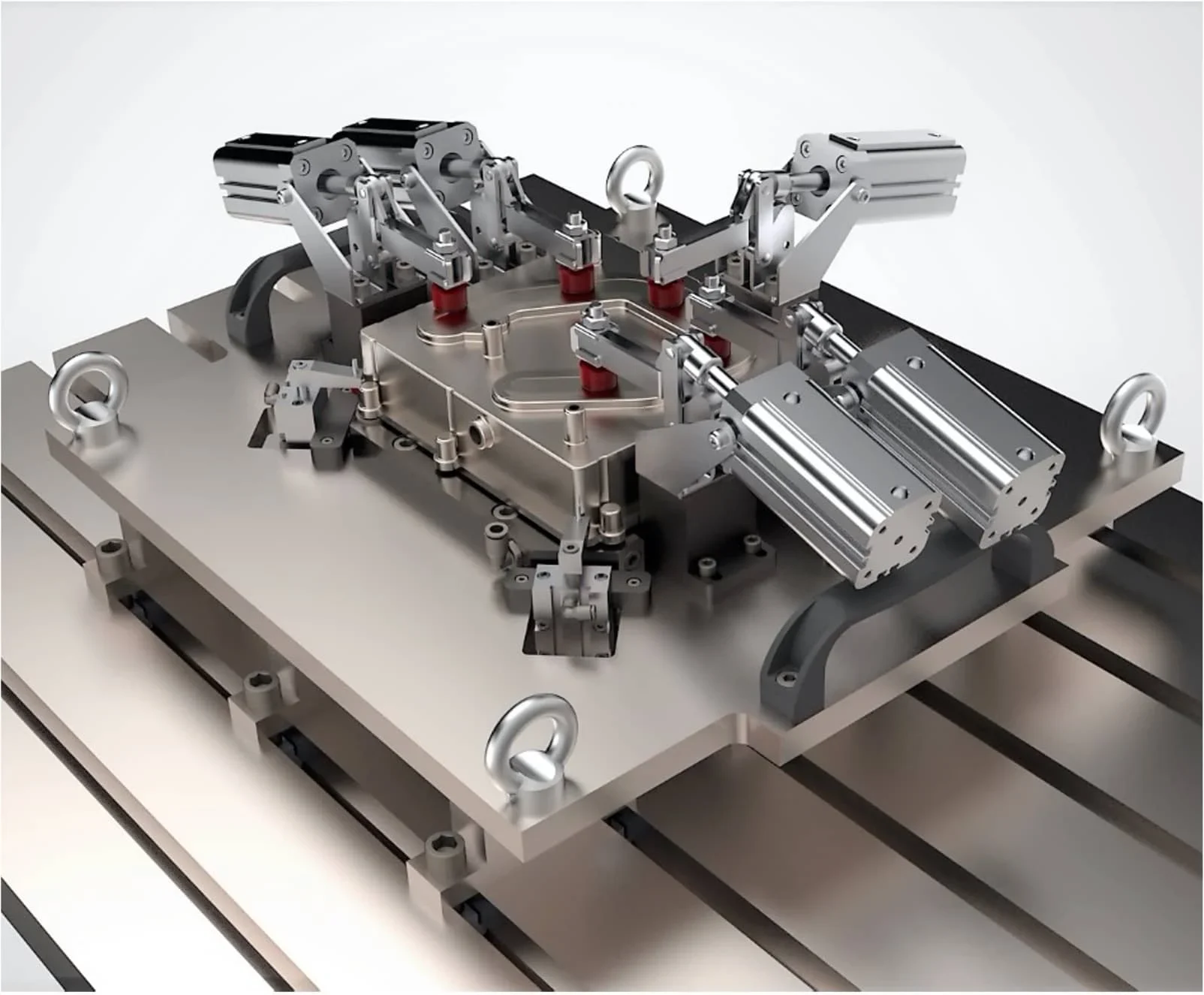

At HM-VH, we specialize in designing and manufacturing high-quality welding jigs tailored to your production needs. Our solutions enhance precision, durability, and workflow efficiency.

Why Choose HM-VH?

- Precision Engineering: Our jigs are designed for exact positioning, ensuring consistent welds.

- Durable Materials: We use high-strength steel and advanced CNC machining for long-lasting performance.

- Custom Solutions: We design jigs to match your specific welding requirements.

- Experienced Team: Our engineers provide expert consultation and innovative solutions for your welding projects.

Contact HM-VH today for custom welding jigs that enhance efficiency, reduce errors, and maximize productivity.

Reviews

There are no reviews yet.