Description

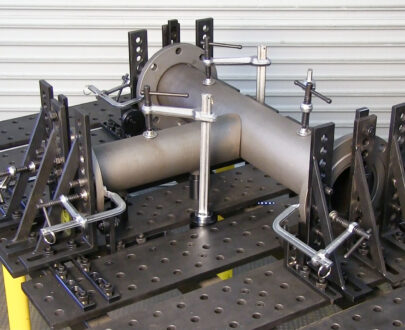

HM-VH specializes in CNC milling services for high-quality mechanical parts, machine components, and precision-engineered parts. Our company offers competitive prices and high-precision machining, with products exported to many countries around the world.

In response to growing market demand and to save on labor costs while maintaining competitive product pricing, HM-VH has invested in a state-of-the-art CNC milling system. Our machines operate smoothly, delivering increasing capacity to meet the highest industry standards.

Product Specifications:

-

Materials: Steel, stainless steel, copper, aluminum, etc.

-

Material type: S45C

-

Hardness after heat treatment: HRC 28-30

-

Precision: ±0.01mm

-

Machining steps: Laser cutting of external contours > Heat treatment > Precision milling > Surface grinding

Material Types for CNC Milling:

During the secondary machining process, the CNC milled parts are customized based on specific designs. CNC milling can be used on various materials, including:

-

Metals

-

Plastics

-

Elastomers

-

Ceramics

-

Composites

-

Glass

When selecting materials for CNC milling, it is crucial to consider their properties and cost-effectiveness. These factors directly affect the quality of the product and help minimize unnecessary machining costs.

Advantages of CNC Milling:

-

High precision and reliable quality

-

Professional service

-

Competitive pricing

-

Guaranteed delivery time

Reviews

There are no reviews yet.