Description

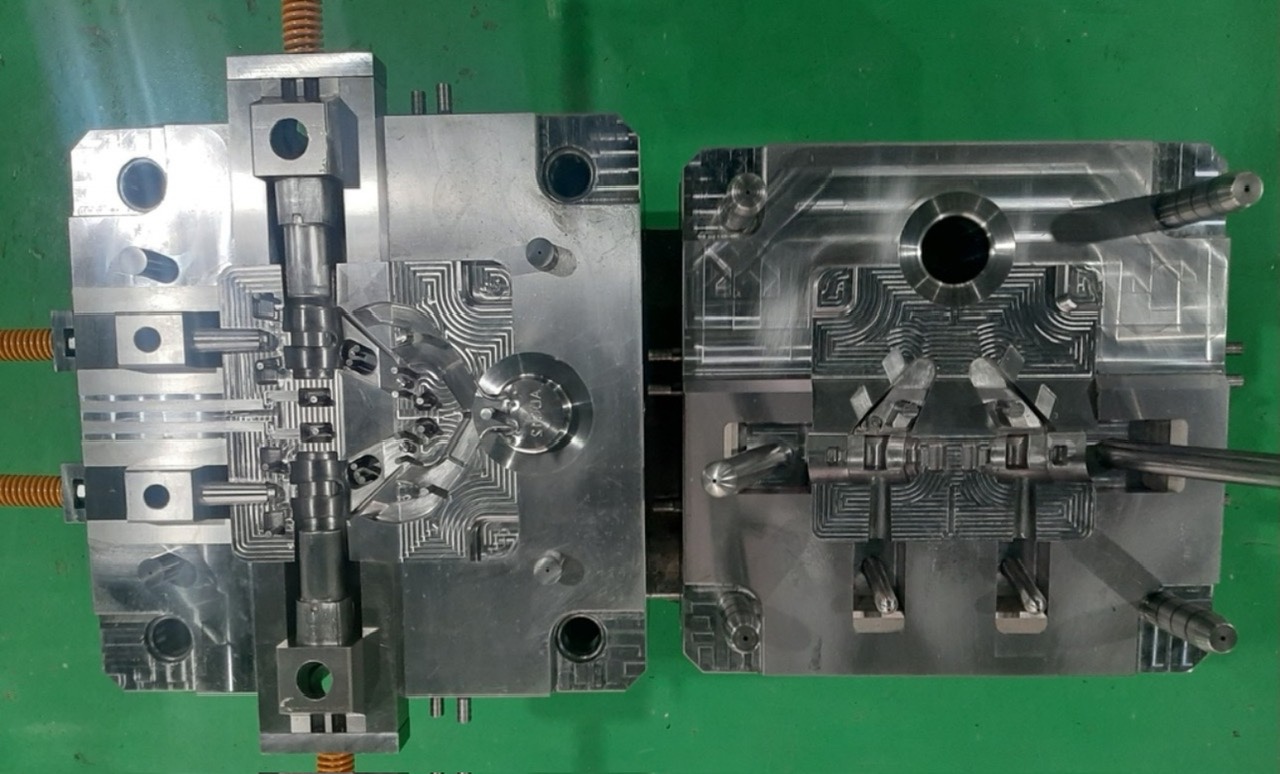

At HM-VH Precision Engineering, we specialize in high-quality die casting mould manufacturing that supports industries such as automotive, electronics, aerospace, consumer goods, and more. Our team combines decades of expertise with state-of-the-art machinery to create moulds that exceed expectations in accuracy, strength, and efficiency.

Die casting moulds are the heart of any die casting operation. A well-designed and precisely manufactured mould can dramatically improve part quality, cycle times, and overall production output. That’s why investing in professional mould-making services from HM-VH is a strategic decision that pays off long term.

Key Advantages of Our Die Casting Mould Manufacturing Services

1. High Precision Engineering

We use advanced CAD/CAM software and CNC machining to ensure the highest level of dimensional accuracy in every mould we produce. This precision allows for flawless casting with tight tolerances and minimal post-processing.

2. Custom Mold Design

Our engineers work closely with you to understand your product requirements and application conditions. We design bespoke moulds tailored to meet your specific volume, material, and performance needs.

3. Durable Tooling Materials

Our moulds are made from high-grade tool steels and heat-treated for enhanced durability and wear resistance. This allows them to withstand high-pressure molten metal injection and extended production cycles.

4. Optimized for Mass Production

We optimize mould design for thermal control and efficient ejection, enabling faster cycle times and smoother part finishes — essential for high-volume manufacturing environments.

5. Cost Efficiency

Our in-house production process, combined with our expertise, enables us to reduce waste, avoid design flaws, and accelerate lead times — saving you money in both tooling and per-part costs.

6. End-to-End Support

From initial concept to final delivery, our team provides full support, including mould design consultation, prototyping, testing, and maintenance services.

7. Industry Compliance

Our moulds are manufactured to meet global quality standards and certifications. We follow rigorous inspection protocols at every stage to ensure top-tier consistency and performance.

Applications

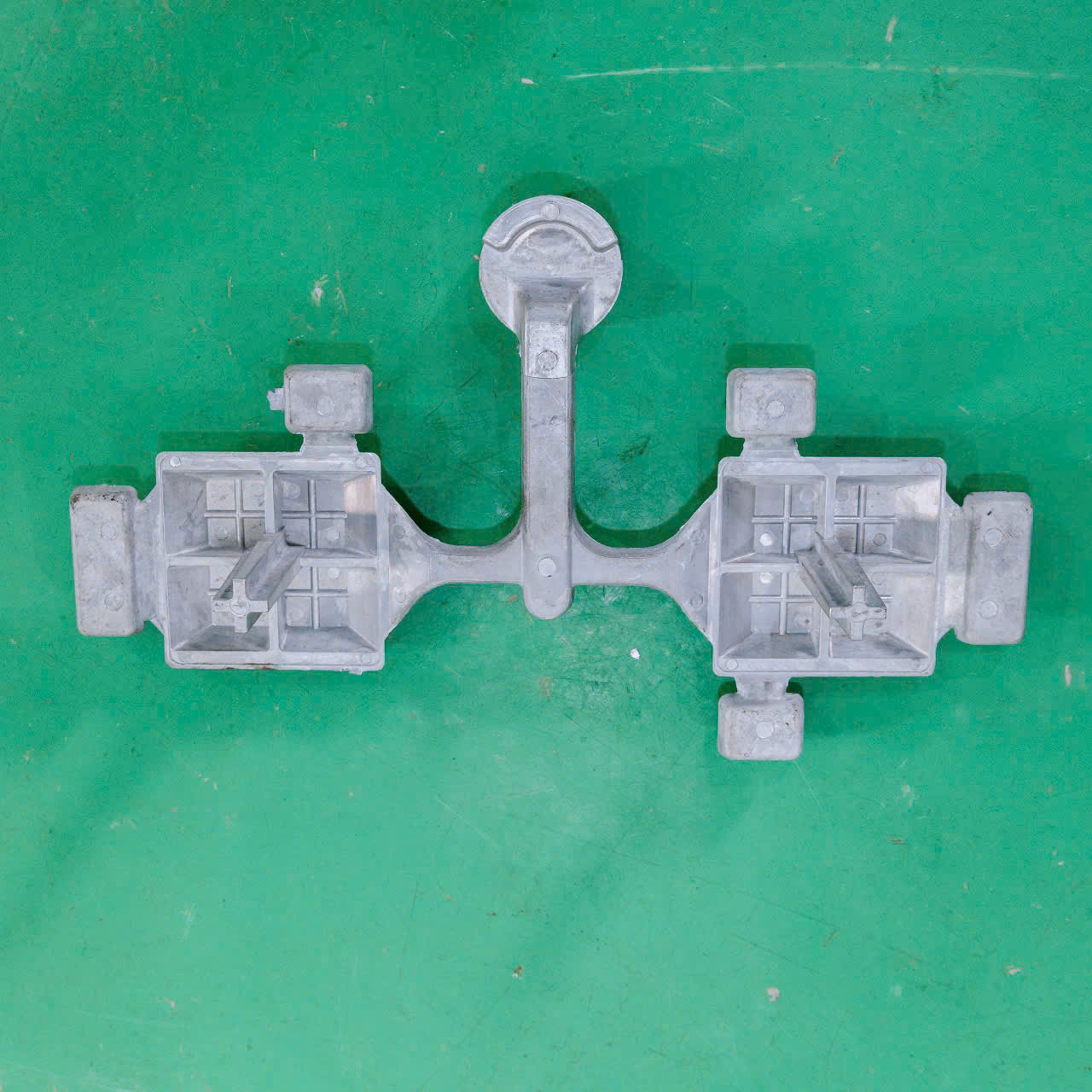

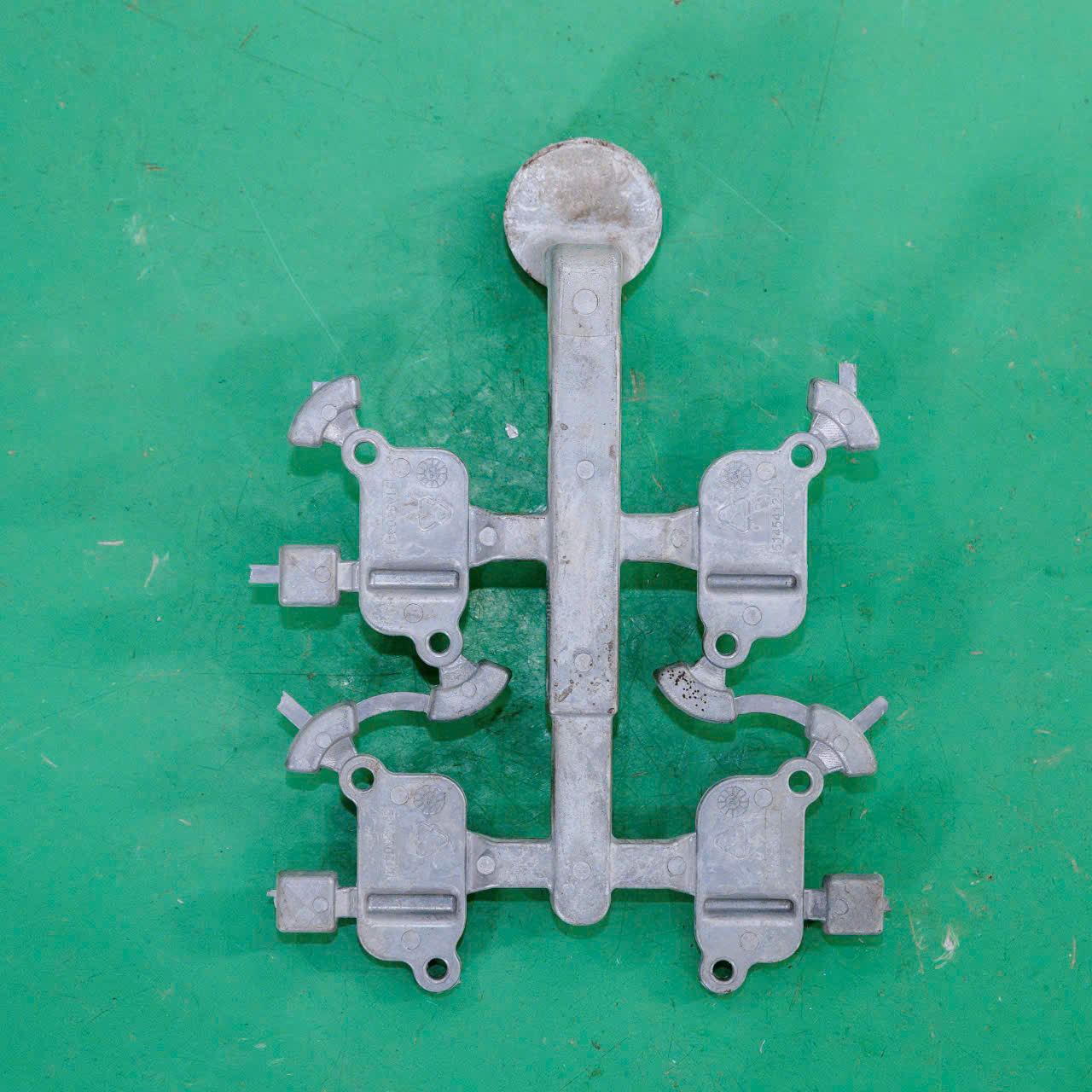

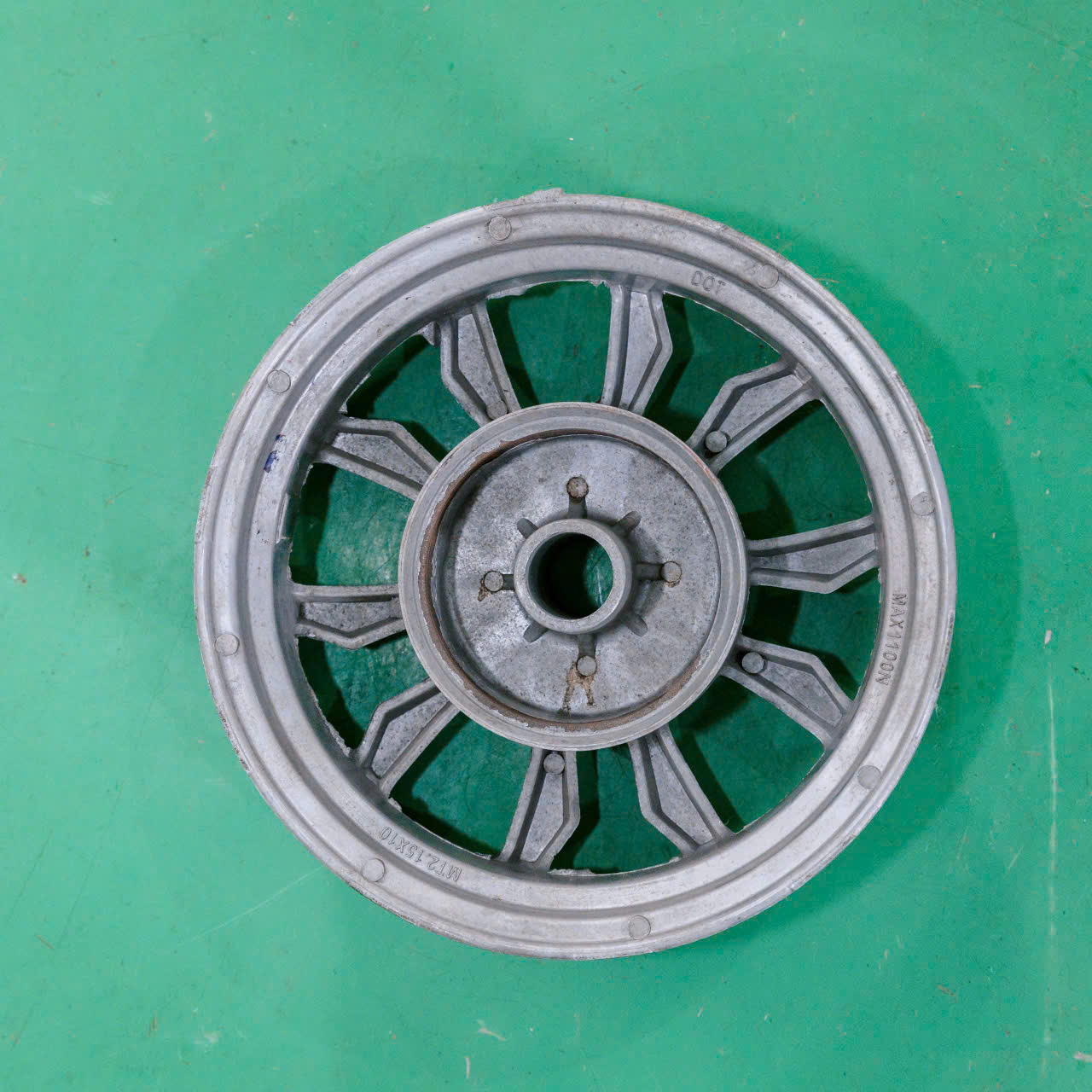

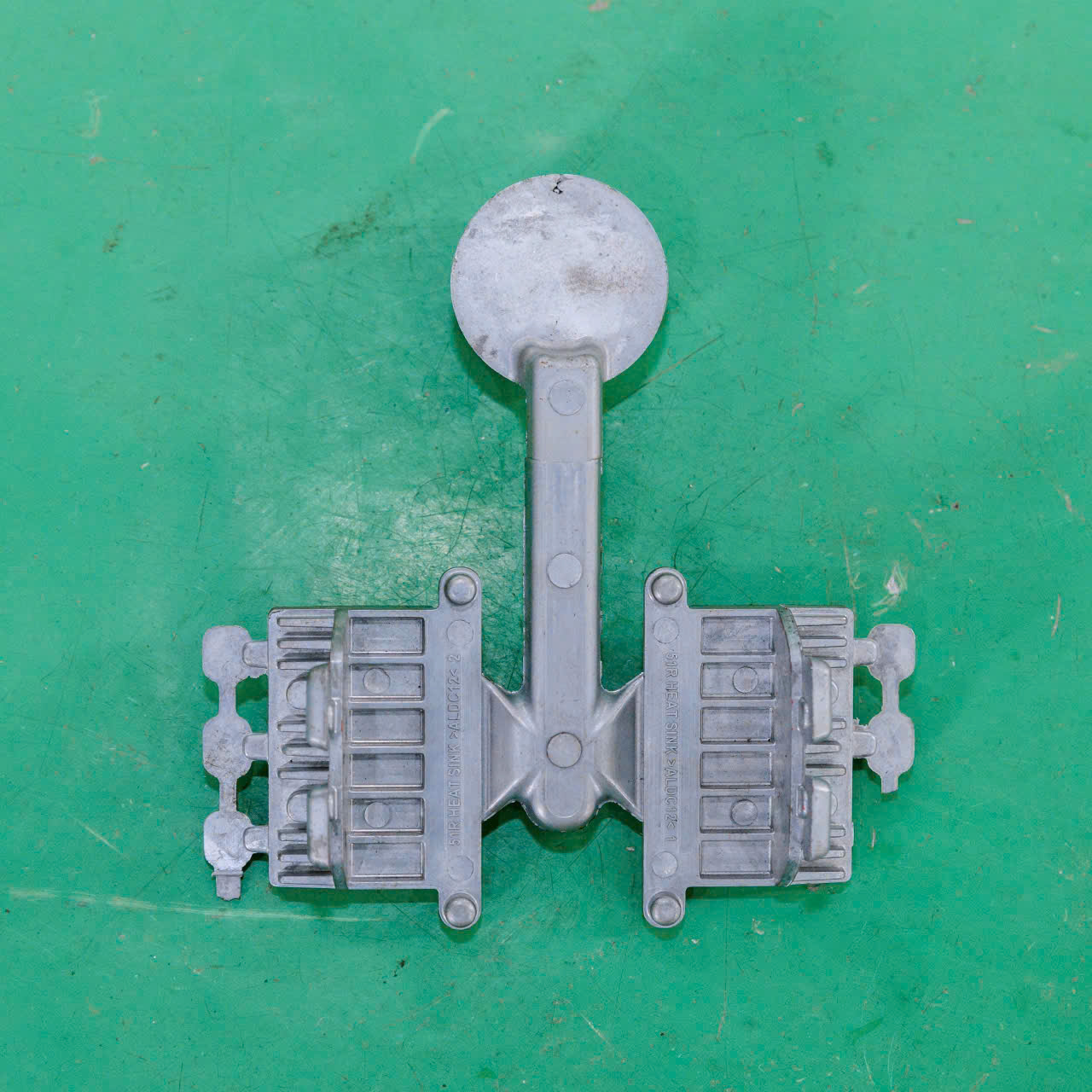

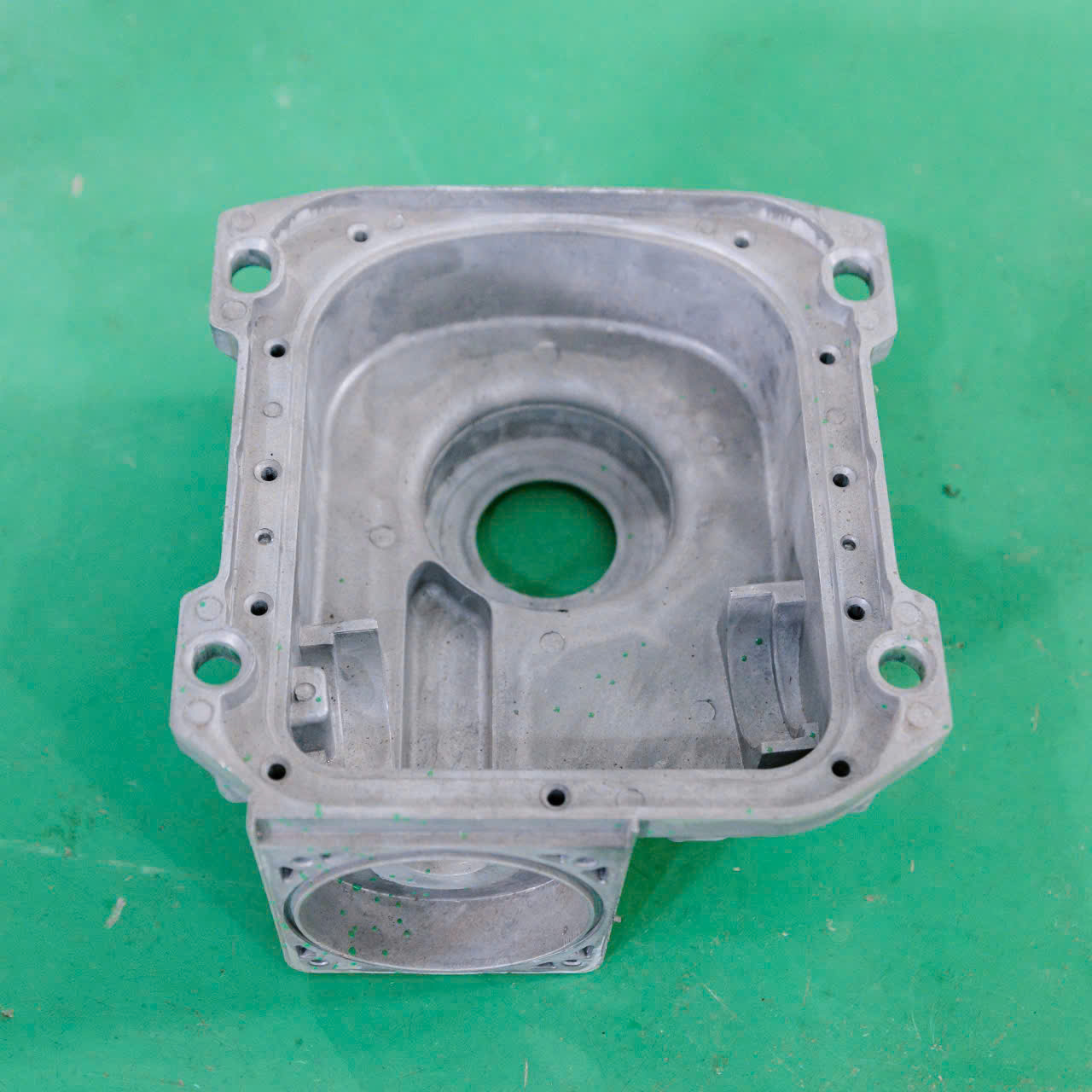

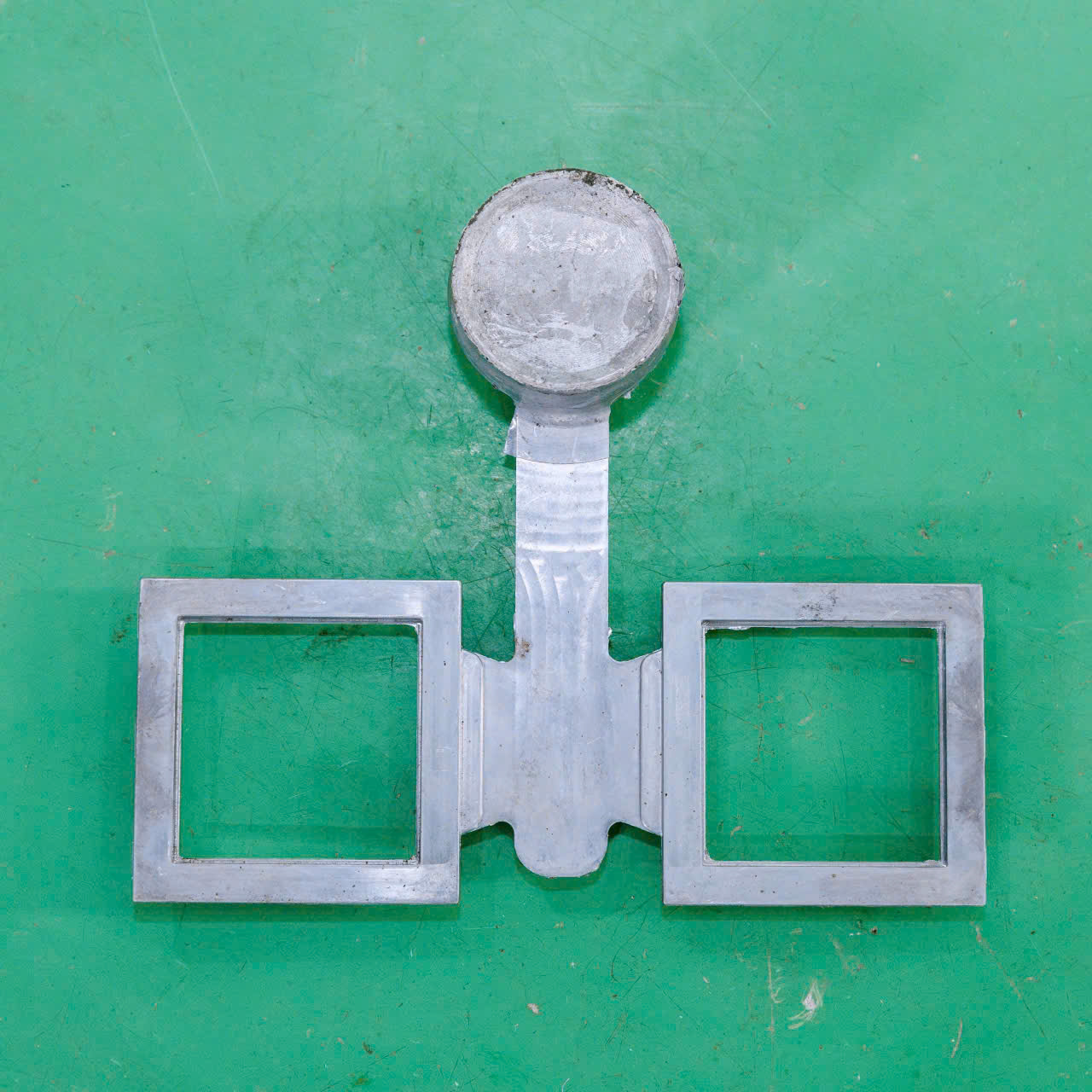

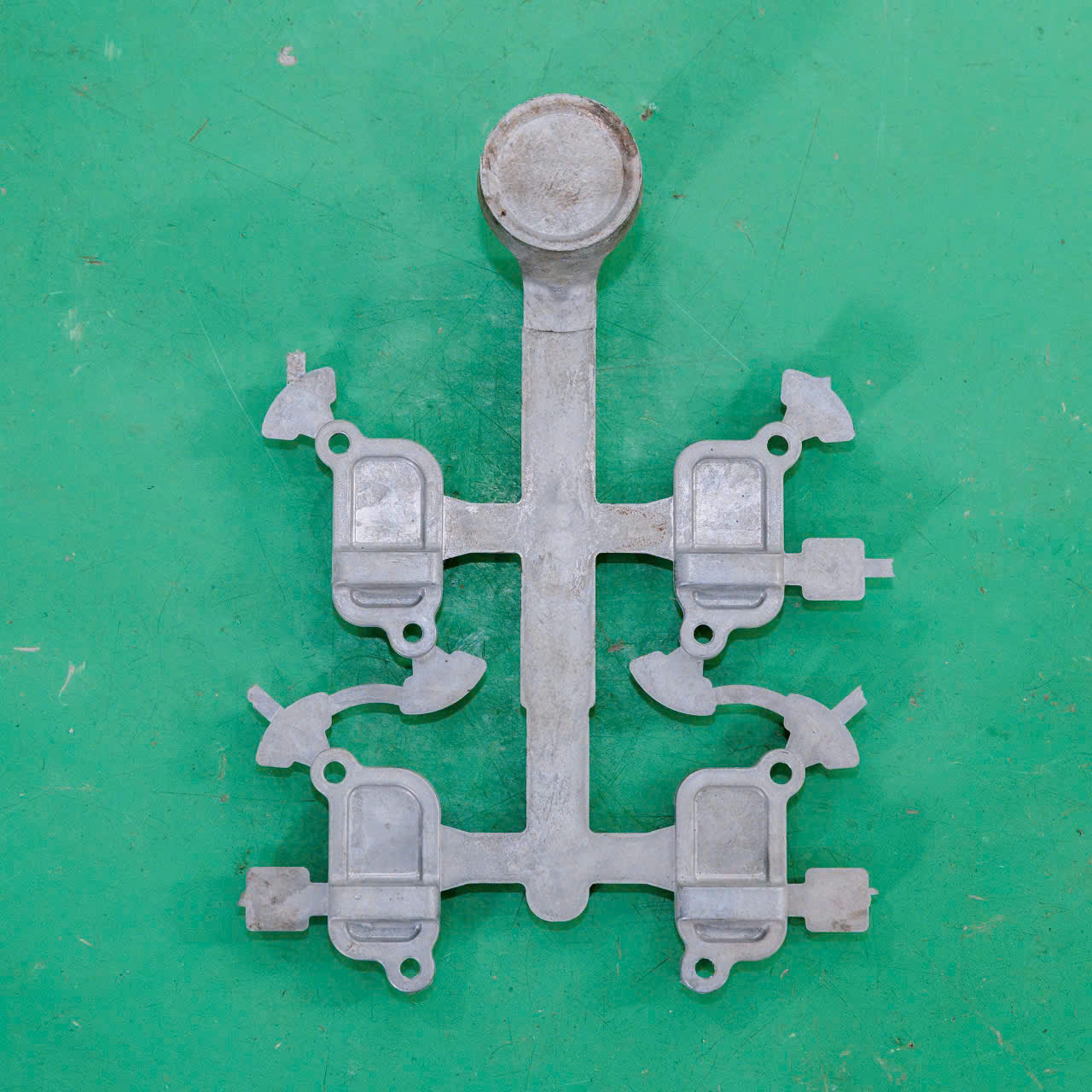

Our die casting moulds are ideal for producing parts in:

-

Automotive components (gear housings, brackets, engine blocks)

-

Consumer electronics (enclosures, heat sinks)

-

Aerospace fittings

-

Industrial machinery parts

-

LED lighting components

Why Choose HM-VH?

-

Years of experience in precision mould-making

-

Skilled technical team with deep knowledge of casting processes

-

Modern factory equipped with CNC, EDM, and wire cutting machinery

-

Competitive pricing with reliable turnaround times

-

Proven track record in delivering complex projects

Whether you are developing a new product or improving an existing one, our die casting mould manufacturing services provide the precision and durability required for your success. Let HM-VH help bring your ideas into shape — literally.

Contact us today to request a quote or discuss your moulding requirements.

Reviews

There are no reviews yet.