Description

Understanding Machine Component Manufacturing

Machine components are small but crucial parts that contribute to the integrity and efficiency of modern machinery.

What is Machine Component Machining?

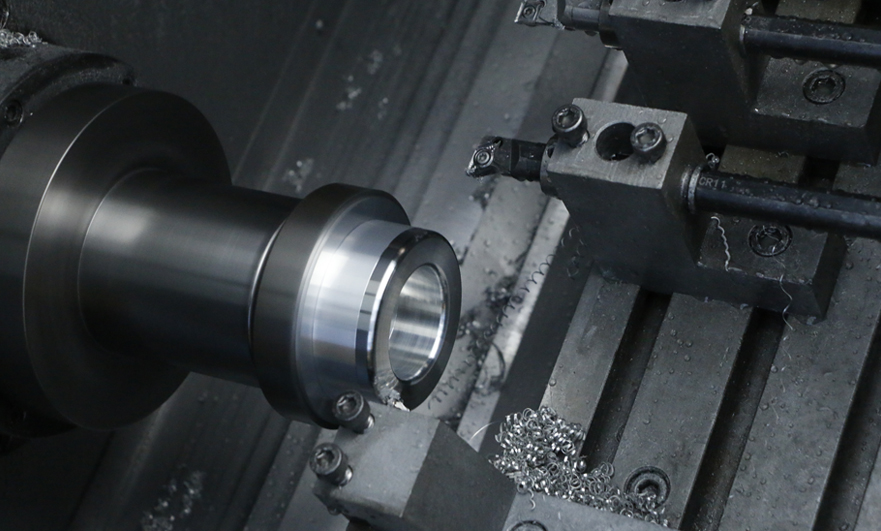

Machine component machining refers to the process of shaping raw materials into precise mechanical parts using material removal techniques. High-hardness component machining involves cutting raw metal blocks into detailed components that require extreme precision and durability. This process demands expert craftsmanship, quality control, and advanced machining technology.

With outstanding precision and mechanical properties, high-hardness component machining is ideal for producing complex tools, long-lasting parts, and high-quality prototypes.

HM-VH’s High-Precision Machining Technology

High-hardness components are often made from strong metals and play a crucial role in mechanical systems. These parts must be manufactured with extreme accuracy to meet customer specifications.

HM-VH utilizes advanced machining technologies, including high-precision CNC machines with automation capabilities, to minimize errors and ensure consistent quality.

Machine Component Machining Process

-

Product Design Analysis – Reviewing detailed drawings, understanding functionality, and assessing technical requirements.

-

Production Type Selection – Choosing between single-piece production, batch production, or mass production.

-

Raw Material Selection – Identifying suitable material and fabrication method for the component.

-

Process Planning – Determining machining steps, setting up workpiece holding positions, and selecting appropriate techniques.

-

Tool & Equipment Selection – Choosing the right tools, fixtures, and setups for optimal machining quality.

-

Machining Execution – Implementing precise machining techniques for each stage.

-

Component Assembly & Processing – Ensuring the proper fit and function of machined parts.

-

Quality Inspection – Conducting final checks to verify accuracy and compliance with design specifications.

Applications of Machine Component Machining

-

Enhances machining efficiency and productivity.

-

Produces highly precise components with minimal errors.

-

Saves time and effort compared to traditional machining.

-

Requires operators to have advanced knowledge of machinery, cutting tools, and CNC operations.

High-Precision Machining Services by HM-VH

HM-VH specializes in custom high-hardness machine component manufacturing using state-of-the-art CNC technology. We deliver precision-engineered parts that meet strict quality standards, ensuring durability and reliability for industrial applications.

Reviews

There are no reviews yet.