Description

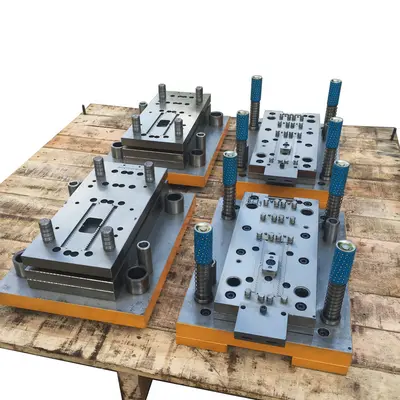

What is a Stamping Mold?

A stamping mold is a specialized tool comprising multiple components assembled into a unit to perform one or more processes on suitable equipment. It creates components with precise shapes and dimensions by deforming materials through bending, pressing, or deep drawing—or by cutting through materials.

What is a Stamping Die?

A stamping die is a tool used in metal stamping processes to shape thin metal sheets at room temperature using applied pressure.

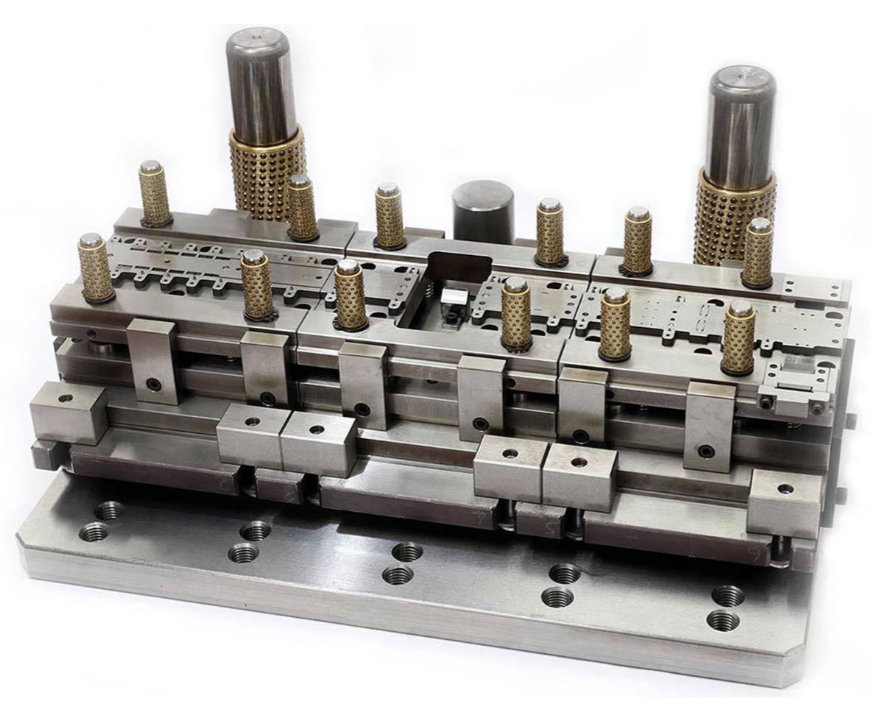

Structure of a Stamping Die

A stamping die consists of two main parts:

-

Upper Die (Punch): The upper portion of the mold, attached to the press hammer, moves up and down to apply force to the metal sheet.

-

Lower Die (Die Block): The fixed lower portion of the mold that holds the material in place.

Types of Stamping Dies

Based on Stamping Methods:

-

Cutting Dies: Used to cut metal sheets through stamping and punching operations.

-

Forming Dies: Used to alter the shape of the workpiece without removing material.

Based on Operational Complexity:

-

Simple Die: Performs a single cutting operation per press stroke, suitable for basic cutting tasks.

-

Compound Die: Executes multiple cutting actions simultaneously, enhancing precision but limiting complex operations.

-

Progressive Die: Conducts sequential forming processes, gradually shaping the part through multiple stages.

-

Transfer Die: Moves the workpiece through different forming stations, producing complete parts in a continuous cycle.

Quality Standards for Stamping Die Manufacturing

-

High wear resistance for extended lifespan.

-

Appropriate hardness and toughness based on function.

-

Compatible material selection based on production volume.

-

Proper lubrication to prevent defects.

-

Strict control of mechanical properties such as durability and resistance to wear.

Applications of Stamping Dies

Stamping dies are used across various industries, including:

-

Household Appliances: Food cans, kitchen utensils, sinks.

-

Automotive: Car bodies, doors, and structural components.

-

Construction: Steel frames, metal doors.

-

Electronics: Components for electrical devices.

-

HVAC Systems: Heating, ventilation, and air conditioning components.

-

Medical Equipment: Surgical instruments and precision tools.

-

Plumbing: Pipe fittings and water system parts.

-

Military: Firearms and ammunition manufacturing.

Materials for Stamping Dies

Common materials for stamping dies include:

-

SKS3: High stability after heat treatment, ideal for cutting and forming.

-

SKS93: High-carbon steel for small production batches, easy to machine and heat-treat.

-

SKD11: Excellent wear resistance under normal conditions, with minimal deformation.

-

DC53: Superior wear resistance, minimal deformation after heat treatment, and better machinability than SKD11.

Stamping Mold Design and Manufacturing Process

-

Force Calculation: Determining cutting force based on sample products.

-

Machine Selection: Choosing the appropriate press machine for the mold.

-

Dimension Calculation: Defining mold dimensions and height.

-

Mold Design: Creating 2D or 3D models for visualization.

-

Machining: Fabricating the mold based on the design.

-

Assembly Inspection: Ensuring proper alignment of mold components.

-

Testing: Running trial operations to verify mold accuracy.

-

Evaluation & Adjustments: Refining the mold if necessary.

Precision Metal Stamping Mold Manufacturing by HM-VH

HM-VH is a leading metal stamping mold manufacturer in Vietnam, offering high-precision custom mold fabrication with advanced machinery and software. Our stamping dies are designed for maximum accuracy, durability, and cost efficiency.

Reviews

There are no reviews yet.